Autool CT150 vehicle petrol injector tester and cleaning machine

Autool CT150 vehicle petrol injector tester and cleaning machine is backordered and will ship as soon as it is back in stock.

Description

Description

Product description:

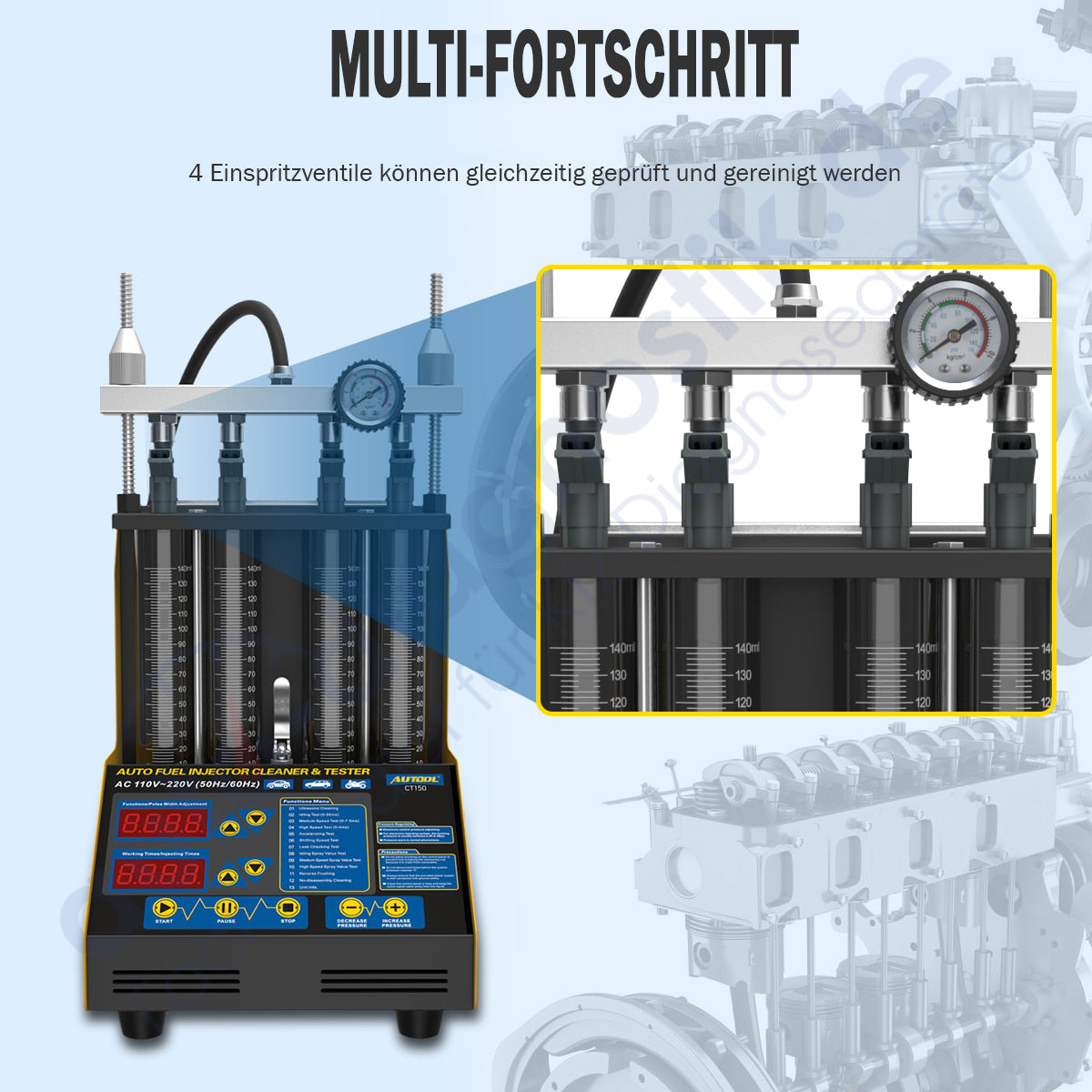

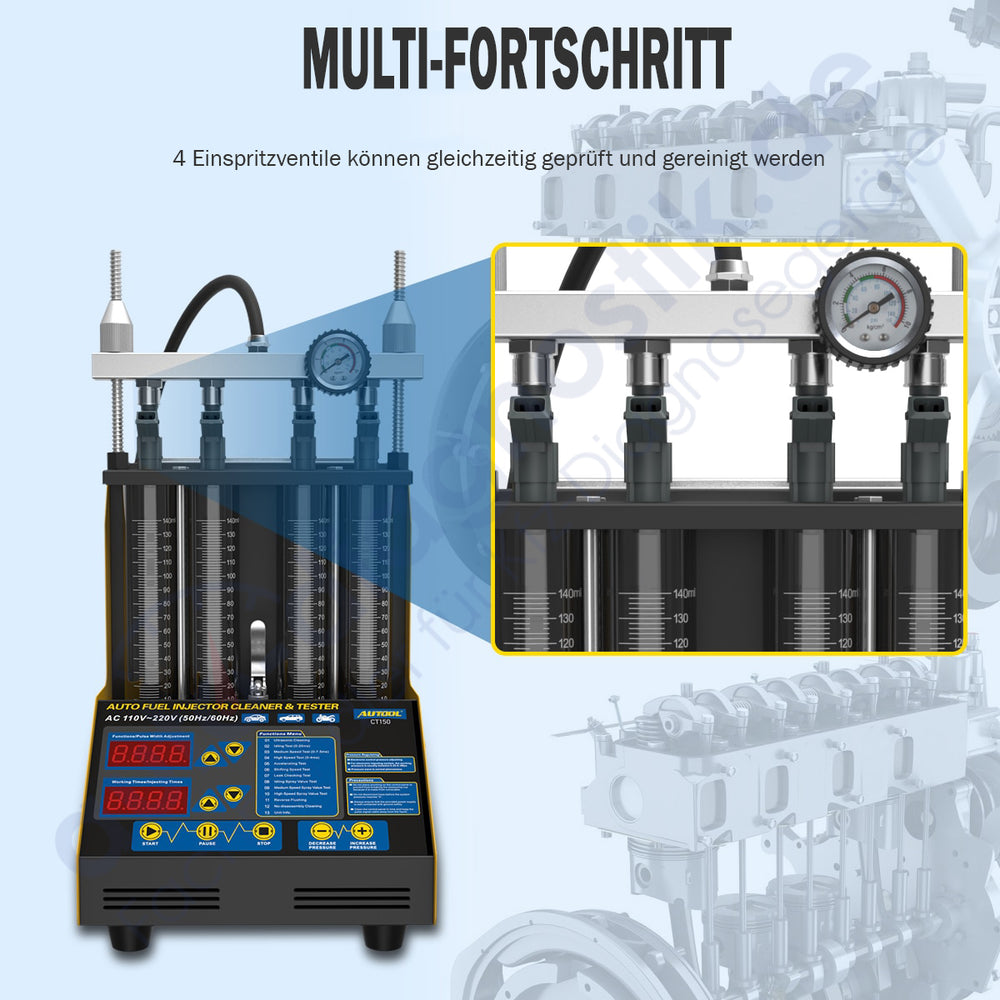

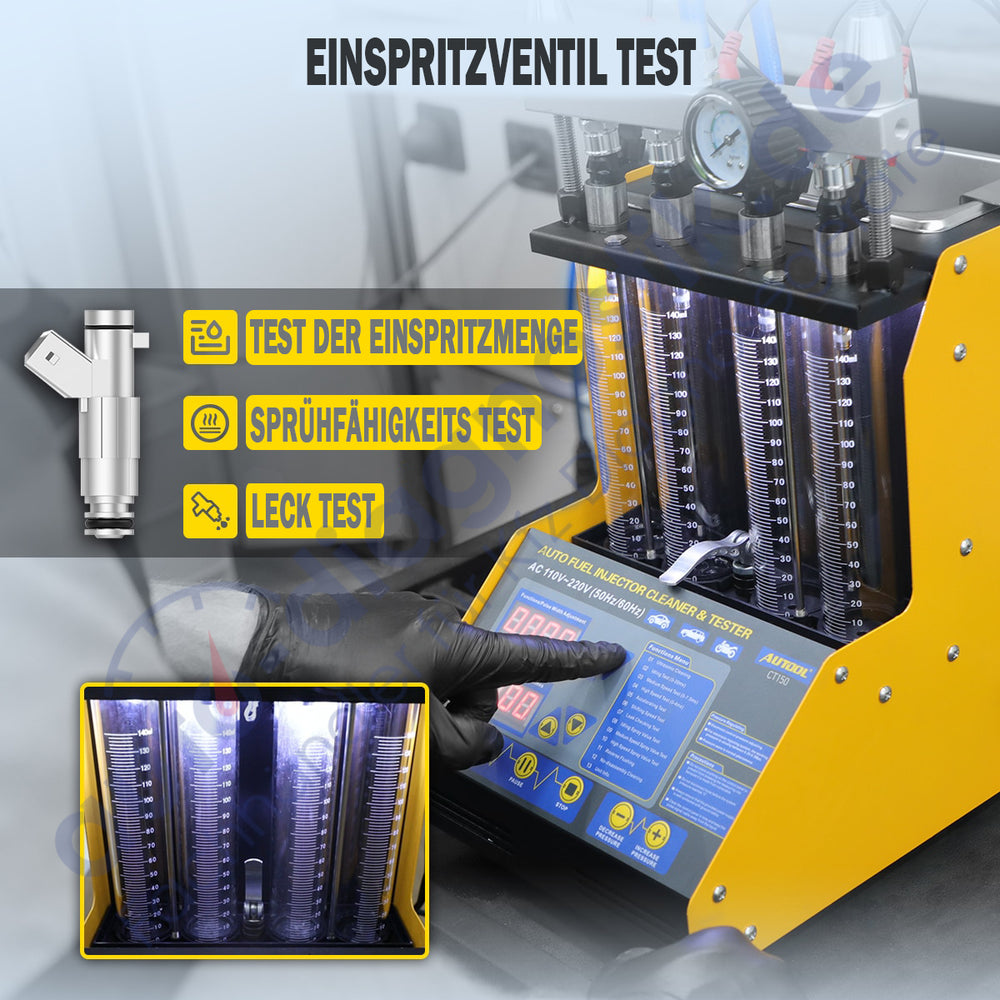

AUTOOL CT150 Car Petrol Injector Tester & Cleaner is a professional 4-cylinder car injector test and cleaning machine.

1. Clean and check the fuel injectors of gasoline cars and motorcycles.

Not suitable for diesel fuel.

2. The fluids to use is 3M car injector cleaning fluid and the test fluid is industrial alcohol.

3. The operating voltage range is 110-230V, supports both 110V and 230V

4. 3 types of power plugs: European, US, Australian power cord

5. CT150 Car Fuel Injector Tester & Cleaner has two versions: English and Russian

6. LED display.

7. 3 years warranty

Supported Models:

Audi, Australia Ford, Benz, BMW, Brilliance, Chevrolet, Chevy, Chrysler, Citroen, Dacia, Dadi, Daewoo, Daihatsu, Demo, Fiat, Ford, GM, Holden, Honda, Hyundai, Isuzu, Jaguar, Kia, Lancia, Land Rover, Mahindra, Maruti, Mazda, Mitsubishi, Nissan, Opel, Peugeot, Porsche, Renault, Romeo, Rover, Saab, Seat, Skoda, Smart, Subaru, Suzuki, Tata, Toyota, Volvo, VW, Yamaha

The CT150 comes standard with two sets of fuel injector connectors, suitable for connecting most injectors.

Main function:

A. Cleaning the injector nozzle with ultrasound

B. Cleaning the spark plug Put the spark plug into the cleaning tank, add the cleaning fluid and start cleaning

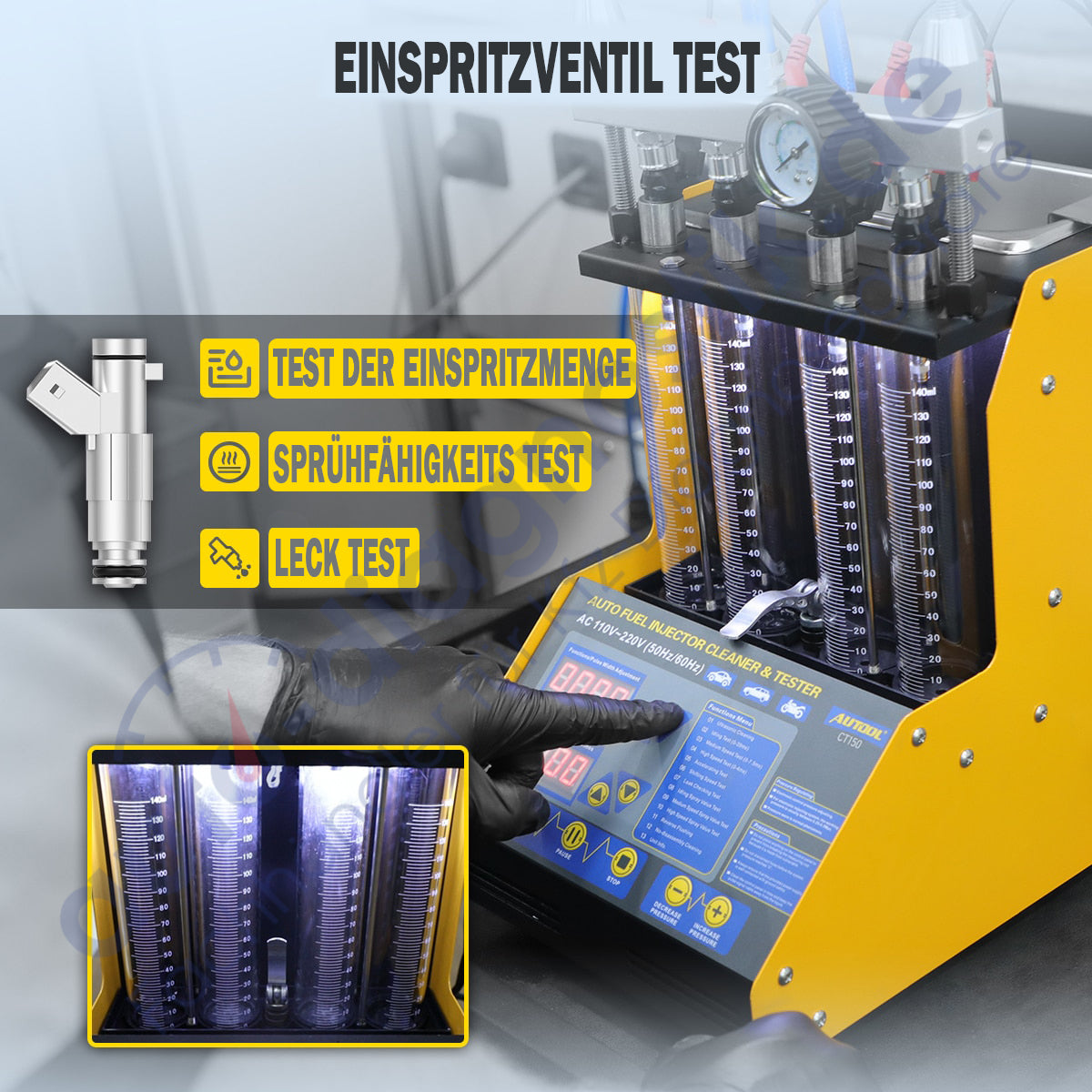

C. Testing the injector in various situations, checking for leaks and clogging

D. Cleaning the injector nozzle without disassembly (requires additional accessories and additional fees, choose yourself)

E. Cleaning the throttle body without disassembly (requires additional accessories and additional costs, choose yourself)

F. Standard configuration for top injection injector nozzles only (Side injection injector nozzle adapter chargeable, choose yourself)

G. Motorcycle fuel injector cleaning and testing (side feed fuel injector adapter for extra charge, choose yourself)

How does this work?

1. Clean the outside of the injector nozzle with cleaning fluid before opening the machine. Place the injectors in an ultrasonic bath after the outside of the injector is free of debris. The cleaning fluid must not extend beyond the connection opening of the impulse line.

2. Turn on the ultrasonic system to allow the ultrasonic energy to dislodge any particles that have accumulated inside the injectors. After cleaning, the remaining cleaning fluid can be reused.

3. Fix the injectors on the main engine and check the injectors for resistance, short circuits and current consumption. The test liquid can be placed in half of the glass tube.

4. Carry out the leak test, the spray pattern and the flow rate test on the flow test bench. The injectors are now returned to the flow test bench for all functions to be checked again.

questions and answers

1. Can you supply the side feed injector adapter? I need to be able to inject from both the top and the side.

The adapter for injection nozzles with side feed is no longer available.

2. Does it support a car's clean fuel system without disassembly? (if it comes with the vehicle-side adapters)

These adapters are not included in the scope of delivery of the CT 150. If you need an additional connection set, please contact me if necessary.

3. Can this clean the direct injectors?

can clean direct injectors

4. Why is there a hole in the ultrasonic pan?

The hole in the ultrasonic tray is used to collect the cleaning liquid.

There is a faucet switch on the back of the device.

If you tighten the tap switch, the cleaning fluid will not flow out.

5. Why does the injector need to be cleaned?

If the engine is suddenly stopped, the gasoline cannot be reused. It would stick to the walls of the injector and combustion chamber.

The gasoline is highly volatile, but wax and varnish remain behind.

When these waxes and varnishes are heated day after day, they are converted into hard parts.

The hard parts form more quickly and in larger quantities when the engine runs on inferior fuel.

Answers to questions about usage

1. No response from the device

Check whether the fuse on the bottom of the right side of the machine is damaged. If it is damaged, please replace the fuse (AC 250V/5A).

2. Oil leak from oil separator unit

If there is oil leakage from the oil separator, please check whether the installed "O" ring fits and whether it is deformed or damaged. If it doesn't fit or is damaged, please replace it. The two black adjusting screws should not be overtightened; overtightening will also cause oil leakage from the oil separator.

3. Oil pressure drops slowly

The oil pressure cannot drop to zero within 1 to 2 minutes, and you can tighten the pressure relief valve counterclockwise with the hex wrench.

4. The buzzer sounds for a long time without oil pressure

The machine is equipped with an oil shortage alarm function. If the fluid level in the oil tank is insufficient, a tone will sound and the oil pump and fuel injector will automatically turn off and stop again later. In this condition, the warning tone will automatically stop after enough cleaning fluid has been refilled. At this time, you need to press the [Run] button to start the oil pump again.

5. The "Drain" button must be pressed twice to completely drain the test solution.

The device's solenoid valve has an automatic shut-off function within 15 seconds; If there is more liquid in the glass tube, multiple emptyings may be necessary.

6. The amount of cleaning and testing solution added

When adding cleaning fluid, the cleaning fluid in the ultrasonic box should not exceed the connection opening of the injection nozzle; When adding test liquid, the test liquid should not be more than two-thirds of the level indicator of the glass tube.

7.Problems cleaning and testing 4 injectors

a short circuit occurs in the machine, which causes the machine's protection to restart. It may be that the injector resistance value is too low or there is a problem with the injector. You need to locate the problematic nozzle and replace it with another, regular nozzle for cleaning. If there is no problem with the injector, one of the pulse lines is damaged. There are 6 pieces of impulse lines, and each impulse line needs to be tested separately. If all 6 pieces of impulse lines can be used normally, the problem is with the fuel nozzle.

Working condition:

Power supply: AC220V/AC110V±10%

Frequency: 50HZ±0.5

Humidity: 85%

Ambient temperature: 040

Magnetic field: 400/m

Sparks and fire are prohibited.

Specifications:

Fuel tank capacity: 2000 ml

Measuring cylinder capacity: 125 ml

Speed range: 0~7500 rpm

Injection times: 0~9900 step: 100ms

PWM pulse: 0~20.0 ms step: 0.1 ms

System pressure: 0~0.6Mpa (adjustable)

Time: 0~20 minutes (adjustable)

Ultrasonic cleaning power: 70W

Ultrasonic cleaning frequency: 28KHZ±0.5KHZ

Weight:10KG

Scope of delivery:

- CT150 main unit

- 4x 14mm cleaning connection

- 4x 17mm cleaning plugs

- 2x pulse signal cable

- Oil separator

- Power cable

- Drain valve for cleaning fluid

- 2x mounting bolts

- 4x washer

- 3x stoppers

- 4x sealing ring

- Ultrasonic cleaning cover

- Ultrasonic cleaning bracket

- funnel

- CT150 User Manual

Shipping and payment conditions

Shipping and payment conditions

FREE SHIPPING FOR ORDERS OVER 50 €!!

The goods are usually delivered by post to the delivery address provided by the customer. When processing the transaction, the delivery address provided by the customer on eBay is decisive. If the payment method selected is PayPal, the delivery address provided by the customer on PayPal at the time of payment is decisive.

If delivery to the customer was not possible and the transport company returns the shipped goods to the seller, the customer bears the costs for the unsuccessful shipment. This does not apply if the customer exercises his right of withdrawal by refusing to accept the goods, if he is not responsible for the circumstances that led to the impossibility of delivery or if he was temporarily prevented from accepting the goods, unless the seller announced the service to him a reasonable time in advance.

You can choose to pay in advance, via PayPal (direct debit and credit card via PayPal) or cash on delivery. If you choose cash on delivery, an additional fee of €9.99 will be charged.

Free shipping within Germany from 50€ value of goods

Shipping costs within the EU are 14,99 €.

The delivery time within Germany is 2-3 working days

Further information

The importance of automotive diagnostic devices for vehicle maintenance

The importance of automotive diagnostic devices for vehicle maintenance

Original diagnostic devices for cars and trucks are indispensable tools for modern vehicle maintenance and repair. These devices make it possible to read error codes generated by the various control units of a vehicle. By using professional diagnostic devices, workshops and vehicle owners can quickly and precisely identify and resolve problems. This increases the efficiency of the repair processes and contributes to the longevity of the vehicles. Professional diagnostic devices also offer advanced functions such as in-depth diagnostics and programming of control units, which is particularly useful for complex repairs and maintenance work. With a vehicle diagnostic device, you can ensure that your vehicle is always in perfect condition.

Why professional diagnostic devices are indispensable

Why professional diagnostic devices are indispensable

Professional diagnostic devices are specially designed for use in workshops and by professionals. They offer comprehensive diagnostic capabilities and support a wide range of vehicle makes and models. These devices can not only read and clear error codes , but also display live data and perform special tests such as actuator tests. They also allow the calibration of control units and the performance of service resets. Thanks to these advanced functions , professional diagnostic devices can make the work of mechanics much easier and improve the quality of the repairs carried out. A professional diagnostic device is therefore an indispensable tool for every professional workshop.

How OBD diagnostic devices work

How OBD diagnostic devices work

OBD (On-Board Diagnostic) systems are standardized diagnostic tools used in almost all modern vehicles. These systems monitor the vehicle's performance and emissions and store error codes when a problem occurs. OBD diagnostic devices can read these error codes and provide detailed information about the condition of the vehicle. This includes monitoring engine parameters, exhaust emissions and other critical systems. By using OBD diagnostic devices regularly, potential problems can be identified and resolved early before they lead to larger and more costly damage. An OBD diagnostic device should therefore be in every vehicle to make car diagnostics efficient and comprehensive.

Auto diagnostics: A key to efficient vehicle repair

Auto diagnostics: A key to efficient vehicle repair

Auto diagnostics includes a variety of techniques and tools for monitoring and analyzing the condition of a vehicle. By using modern original diagnostic devices for cars and trucks Mechanics can carry out precise fault analyses and make targeted repairs. This not only saves time, but also costs for the vehicle owner. Modern diagnostic devices also offer the option of carrying out software updates and making adjustments to the vehicle control units. This is particularly important for optimizing vehicle performance and adapting to individual requirements. The continuous development of diagnostic technology helps to ensure that vehicles can be operated more safely and efficiently. With a reliable car diagnostic device, you always have all the important information at hand to optimally maintain and repair your vehicle.