Fuel Injector Tester & Testing Device – Precision for Professional Vehicle Diagnostics

The fuel injection technology in modern vehicles is complex, sensitive, and crucial for performance. Therefore, it's essential to regularly check the condition and function of the fuel injectors. A high-quality fuel injector tester or test device is the perfect tool for this. Whether in a professional workshop or for ambitious DIY mechanics, the right fuel injector tester allows you to quickly identify and rectify faults – before they lead to costly consequential damage.

Why an injector tester is indispensable in the automotive sector

Fuel injection plays a central role in every combustion process in the engine. It determines performance, fuel consumption, and emissions. If the injectors are dirty, damaged, or incorrectly controlled, the entire engine operation suffers. This is where injector testers come in: They check whether the injector is spraying correctly, whether it is sealed, and whether the injection quantity is correct.

A professional fuel injector tester enables precise fault analysis without disassembling the entire system. It saves time, avoids unnecessary part replacement, and helps with targeted repairs. Regular testing is essential, especially for vehicles with direct injection (GDI, TSI, JTD, HDI, etc.).

Applications for fuel injector test equipment in automotive diagnostics

Fuel injector testers have a wide range of applications, covering both gasoline and diesel vehicles. Workshops, testing stations, and mobile service providers use these devices daily to make precise diagnoses. Fuel injector testers are also increasingly used in used car inspections and for assessing high-mileage engines. They help to objectively evaluate a vehicle's technical condition and make informed decisions about repair or maintenance.

Testing of gasoline injectors

Especially with gasoline engines featuring direct injection, problems such as carbon buildup or uneven injection quantities frequently occur. An injector tester allows you to compare spray patterns, measure flow rates, and detect leaks. It also enables precise evaluation of the injector's function at different pulse widths. Additionally, load conditions and various engine speed ranges can be simulated to test the injector's behavior under realistic conditions. This allows you to determine early on whether cleaning is sufficient or if replacing the injector is technically advisable.

Diagnosis of diesel injection systems

Diesel injectors operate at very high pressure and are particularly susceptible to blockages and wear. A good injector tester simulates various load conditions and tests the injector's response. This allows for the early identification of defective or inconsistently functioning injectors. Especially in common-rail systems, a precise assessment of the return flow rates and injection characteristics is crucial to prevent consequential engine damage. Based on the measurement results, you can make an informed decision as to whether individual injectors need to be repaired, replaced, or whether the entire system requires further inspection.

Electrical control check

Many modern fuel injector testers are capable of analyzing the electrical signal processing of the injectors. This verifies whether the control unit is controlling the injectors correctly and whether the injector's response matches the expected behavior. This is particularly important for systems with variable injection strategies. At the same time, interruptions, loose connections, or faulty plug connections in the wiring harness can be identified more quickly. The combination of electrical analysis and mechanical testing provides a complete picture of the fuel injection system's condition.

Advantages of a professional fuel injector tester

A high-quality fuel injector tester is more than just a diagnostic tool – it's a key element of modern vehicle maintenance. Here's an overview of the most important advantages: Reproducible measurements and documentable results significantly improve the quality of your diagnostics. Furthermore, test results can be presented to the customer in an easily understandable way, which greatly enhances the transparency of your recommendations.

Rapid fault localization

Instead of replacing parts based on suspicion, an injector tester provides concrete indications of defective injectors. You can immediately see which injector is not working correctly and intervene in a targeted manner. This reduces the error rate during diagnosis and avoids unnecessary returns after repairs. At the same time, you save valuable working time, as systematic testing procedures can be made significantly more efficient.

Comparative measurements possible

Many devices offer the option of testing all four, six, or eight injectors simultaneously. This allows you to directly compare and document differences in spray pattern or injection quantity. Especially with slight variations between cylinders, irregularities can be detected that are only perceived as a "subjective loss of power" while driving. The recorded comparative values can also serve as a basis for subsequent control measurements after a repair.

Cost reduction through targeted repairs

A faulty injector can lead to loss of power, increased fuel consumption, or engine damage. Using a diagnostic tool allows you to prevent such problems early on – saving you expensive repairs and unnecessary downtime. Instead of replacing entire component packages, you can selectively replace individual parts, significantly reducing material costs. This transparency has a positive impact on customer satisfaction, as necessary work can be clearly explained.

Ideal for workshops and testing facilities

Whether for routine checks or troubleshooting – a good fuel injector tester belongs in every well-equipped workshop. It increases efficiency and builds customer trust through transparent results. Test benches with a well-structured user interface also allow even less experienced personnel to be safely involved in the testing process. This makes fuel injector diagnostics an integral part of your service offerings and expands your range of services.

Fuel injector tester with cleaning function – 2-in-1 solution

Some fuel injector testers also feature an integrated cleaning function. This allows you to not only test the injectors but also clean them simultaneously – without removing them. This combination significantly reduces the workload and makes the device particularly economical. Furthermore, this 2-in-1 solution is ideal for service campaigns where customers expect a noticeable improvement in engine performance and fuel consumption.

Cleaning without disassembly

By introducing special cleaning fluids, the injector is flushed while installed. This saves time and prevents the risk of assembly errors. This method is particularly effective for light carbon deposits. At the same time, the vehicle often remains drivable, making the procedure easy to integrate into normal workshop procedures. For customers, cleaning without disassembly is frequently the most attractive option, as it is more cost-effective than a complete replacement.

Restore function without leaving any residue

Deposits significantly impair injection quality. A combined tester and cleaner allows for the targeted removal of such residues. This improves fuel consumption, performance, and the engine's emissions. In many cases, this can also resolve issues during emissions testing without requiring extensive repairs. For high-mileage vehicles, regular cleaning is an important factor in maintaining their value.

Sustainable maintenance for long-term use

Regular cleaning and inspection increase the lifespan of injectors. This reduces maintenance costs in the long run and ensures consistently stable engine operation – a clear advantage for frequent and long-distance drivers. Furthermore, the strain on other components in the fuel system is reduced, as they have to cope less with dirt particles and insufficient fuel levels. Workshops can offer such measures as preventative service packages, thus evolving from mere "troubleshooters" to comprehensive maintenance partners.

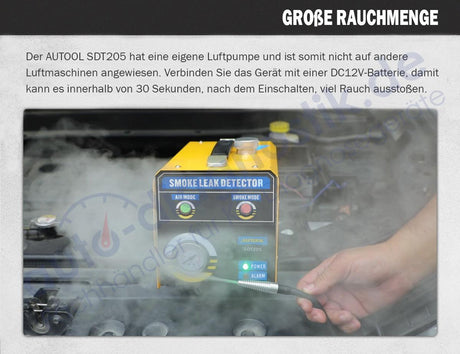

Combination with smoke leak detectors for comprehensive system testing

A faulty injector is often just the tip of the iceberg. Leaks in the intake manifold, charge air system, or exhaust gas recirculation also affect injection. Therefore, combining an injector tester with a smoke leak detector is worthwhile. Only when both areas – injection and air intake – are thoroughly tested can a coherent overall picture of the engine management system be obtained. This effectively prevents misdiagnoses caused by overlooked vacuum leaks.

Locating the smallest leaks

Smoke leak detectors introduce visible smoke into the system, instantly revealing leaks. This allows you to quickly locate and fix problems, for example, in the EGR system, intercooler, or intake manifold. Even hairline cracks, porous vacuum hoses, or loose clamps are made visible. Combined with the readings from the fuel injector tester, you can clearly distinguish whether the problem lies in the fuel or air system.

Efficient troubleshooting in the overall system

The combination of mechanical testing (tester) and leak detection (smoke detector) provides a complete picture of the system. This ensures targeted repairs without unnecessary parts replacement experiments. This approach is significantly more reliable, especially for complex fault patterns with multiple error codes in the engine control unit. At the same time, it reduces diagnostic time, noticeably improving the efficiency of the workshop.

Recommendation for workshop equipment

A set consisting of an injector tester, cleaning device, and smoke leak detector offers workshops a professional, comprehensive solution. This allows for the reliable diagnosis of virtually all typical injection and mixture problems. Such equipment increases independence from external service providers and generates additional value within the workshop. Furthermore, an expanded diagnostic range enables you to reach new customer groups, such as fleet operators or specialized tuning customers.

What should you look out for when buying an injector tester?

Not every device is suitable for every workshop. The requirements differ depending on the vehicle type, engine design, and intended use. Therefore, pay attention to the following criteria: In addition to the technical specifications, ease of use, service availability, and manufacturer support also play an important role. A well-documented device with user-friendly software makes it easier to get started and reduces training requirements.

Compatibility with injection systems

A good tester should be suitable for both gasoline and diesel injectors. Many modern systems require special adapters or test protocols – make sure your device supports these. Support for current direct injection systems (GDI, FSI, TSI, etc.) is equally important so you can also test newer vehicles. Check whether the manufacturer regularly offers updates or expansions to integrate future systems.

Number of test channels

Depending on the workshop size and vehicle type, it can be advantageous to be able to test multiple injectors simultaneously. Devices with 4 or 6 channels enable time-saving serial testing, for example, for vehicle fleets. For high-performance or multi-cylinder engines, additional channels can further accelerate the testing process. This allows for the efficient execution of extensive test series as part of tuning projects or engine overhauls.

Display and evaluation

A digital display with live data is essential. High-quality devices show spray patterns, flow rate, and electrical impulses. Some models even offer PC connectivity for documentation. This allows you to save and print test reports and share them with customers or business partners. A clearly structured user interface also reduces the potential for operating errors.

Accessories and spare parts

Check whether the device comes with suitable accessories such as cleaning adapters, test lines, or spray chambers. Spare parts should be easy to reorder to avoid lengthy downtime. A wide range of accessories also makes it easier to use the device on different vehicle makes and injection systems. Also, pay attention to the availability of wear parts such as seals or filters to ensure the device operates reliably in the long term.

Who would benefit from an injector tester?

An injector tester isn't just useful for large workshops. Smaller businesses, mobile service providers, and ambitious mechanics also benefit from the capabilities of these devices. The key factor is how frequently you deal with injection problems and whether you want to handle these tasks in-house in the future. In many cases, the investment pays for itself faster than expected because it reduces the need for outsourcing and the risk of misdiagnosis.

Professional workshops

For fault diagnosis, service preparation, or as part of the annual inspection – a diagnostic tool is the ideal complement to traditional OBD diagnostic equipment. It builds trust through transparent test results and enables well-founded cost estimates. At the same time, you position your workshop as a competent partner for complex engine issues. Especially with discerning customers who own modern vehicles, professional injection system diagnostics are a compelling selling point.

Mobile service technicians

Thanks to their compact design and ease of use, many models are also suitable for mobile applications. This allows you to check fuel injectors on-site at the customer's location and clean them immediately if necessary – ideal for breakdown services or service vehicles. This reduces towing costs and makes your service significantly more attractive, as problems can be assessed directly at the scene. This flexibility is a real competitive advantage, especially in the fleet and agricultural sectors.

Hobby mechanics and tuning fans

Those who work on their own vehicles can save on expensive workshop costs by using an affordable fuel injector tester. Self-testing is particularly worthwhile for minor issues such as rough engine running or increased fuel consumption. For tuning enthusiasts, this also opens up possibilities for better monitoring the injection system's performance after modifications. However, it is crucial to observe the safety instructions and manufacturer's guidelines to avoid damaging the injection system.

Recommended fuel injector testers for workshop and diagnostics

For precise testing and cleaning of injection systems, devices that offer both reliable diagnostics and an integrated cleaning function are ideal. The following models have proven particularly effective in professional workshop settings and cover both gasoline and direct injection (GDI) systems. When selecting a device, ensure that the manufacturers provide reliable technical support and easily accessible service information. This will guarantee that your testing and cleaning equipment will meet the demands of everyday workshop use in the long term.

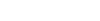

Autool CT200 – Original Automotive Petrol Injector Tester & Cleaner

- 2-in-1 device for testing and cleaning gasoline injectors

- Supports various spray patterns, leak and flow tests

- Suitable for 4-cylinder engines and universally applicable to cars and motorcycles.

- Transparent measuring cylinders allow for direct comparison of injection quantities.

- Includes ultrasonic cleaning function for thorough injector cleaning.

Autool CT400 GDI – Injector Tester for High-Pressure Systems

- Specifically developed for GDI, FSI, TSI and other high-pressure injection systems

- Simulates various operating states for precise functional testing

- Cleaning function with adjustable frequency and pressure for realistic simulations

- Ideal for professional workshops focusing on modern petrol engines

- Stable construction with a clear user interface and precise controls

With the Autool CT200 and the Autool CT400 GDI, you get powerful workshop solutions that significantly simplify the diagnosis and maintenance of modern injection systems. Both devices ensure reproducible results, efficient cleaning, and therefore trouble-free engine operation.

Fuel Injector Tester – The testing device for modern engines

A professional fuel injector tester is a must-have for anyone who regularly works with vehicle technology. Whether for diagnosis, maintenance, or cleaning – with the right fuel injector tester, you can identify problems early and prevent costly engine damage.

At auto-diagnostik.de you'll find a wide selection of fuel injector testing equipment , suitable for various engine types and applications. Whether you need simple testers for hobby mechanics or professional systems for workshops – here you'll find the right equipment for precise diagnostics and reliable maintenance.